AnyBike

In this post, I’ll talk about a project I made my freshman year of college with my roommate Life Rouby. It was an e-bike conversion kit that we made for the SPARK competition.

What is SPARK?

SPARK is a year-long program at Clemson that helps students turn ideas into viable businesses. They teach pitch development, market research, and prototyping. Each week, participants meet to gain feedback on their pitches and share progress. It all concludes with a competition in March where teams compete to see who has the best pitch.

What was AnyBike?

AnyBike was an e-bike conversion kit that was designed to turn any bike into an e-bike. The idea came from riding around Clemson’s campus and realizing that buying an e-bike is expensive, conversion kits are expensive, and most people already own bicycles. I wanted a cheaper, DIY option that would make it easy for anyone to get back to riding.

The final design was using a friction-drive motor mounted near the rear wheel, a battery under the top tube, and a wireless throttle on the handlebars. It could be installed or removed in minutes while staying affordable.

Design Iterations / Timeline

Initial Idea

The first prototype attempted to use parts from an old electric scooter. I wanted to try and use the motor to create a hub-style e-bike.

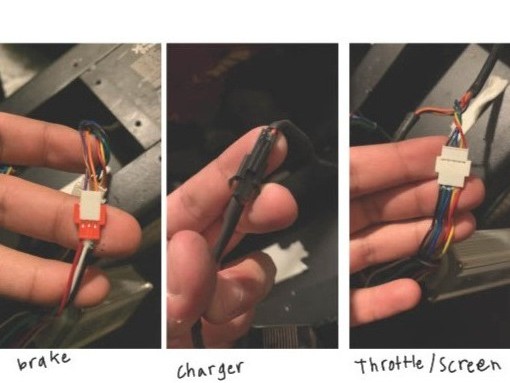

Switching to Friction Drive

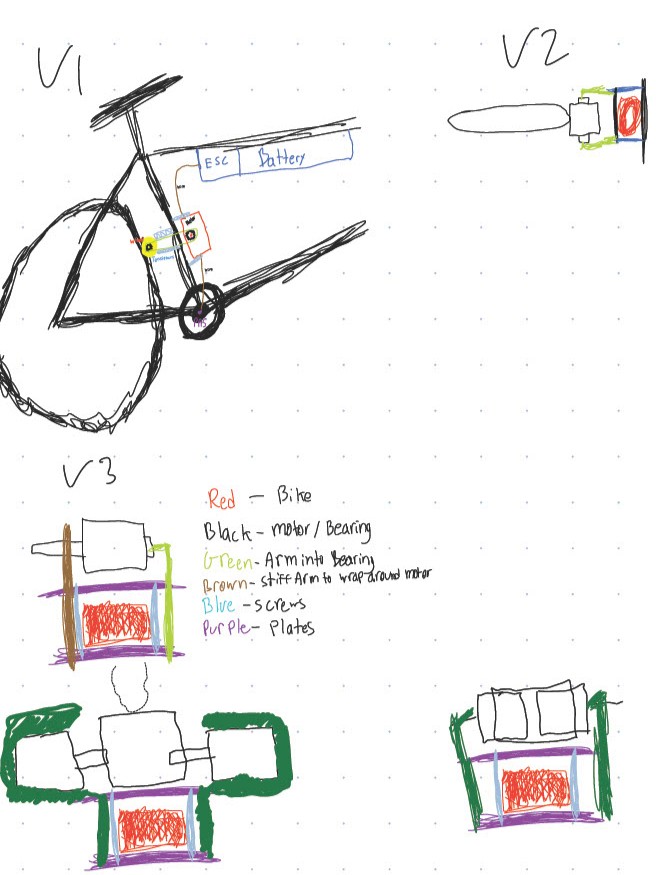

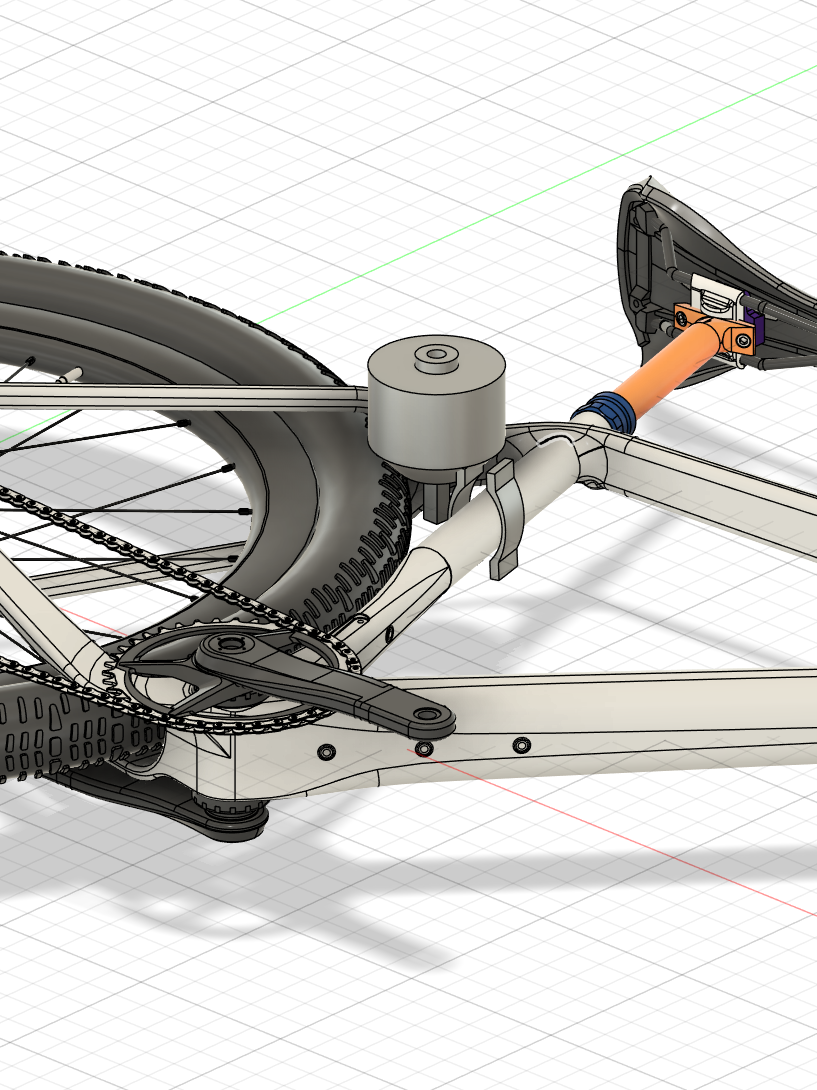

That did not end up working well at all, so I utilized SPARK seed funding to purchase electric scooter components. I had decided on doing some sort of friction drive at this point, so most design efforts were focused on how we would mount the motor. We knew that we were going to use a wireless throttle, and that the battery was going to be under the top tube. The motor had a few options, and we decided to put it against the seat tube and the rear wheel. That way the motor would have enough leverage to be able to provide power to the rear wheel.

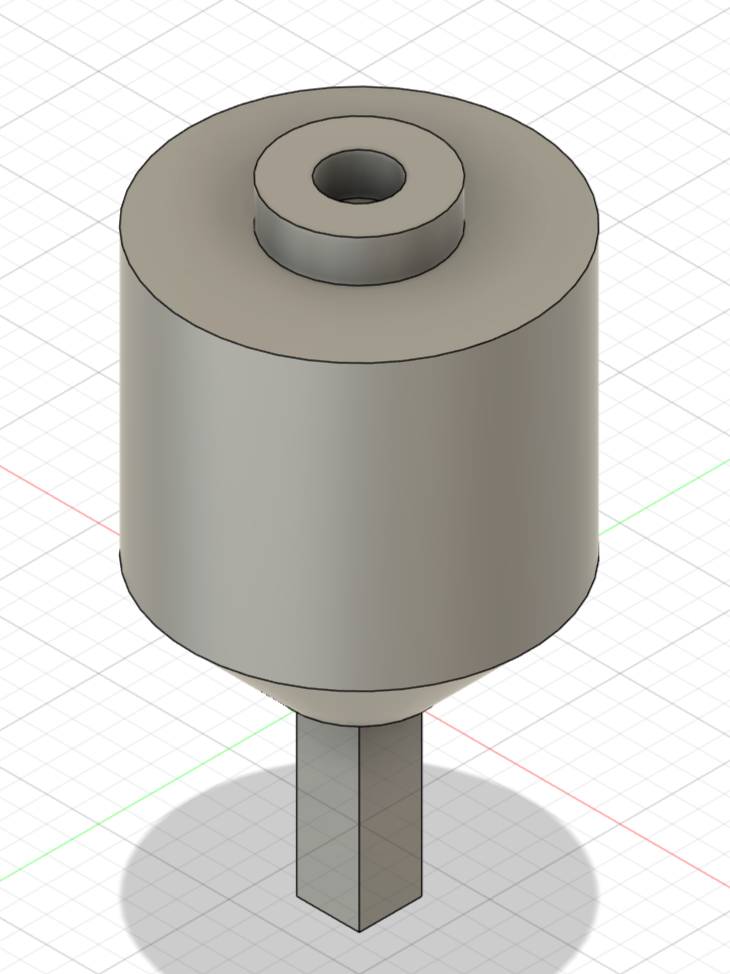

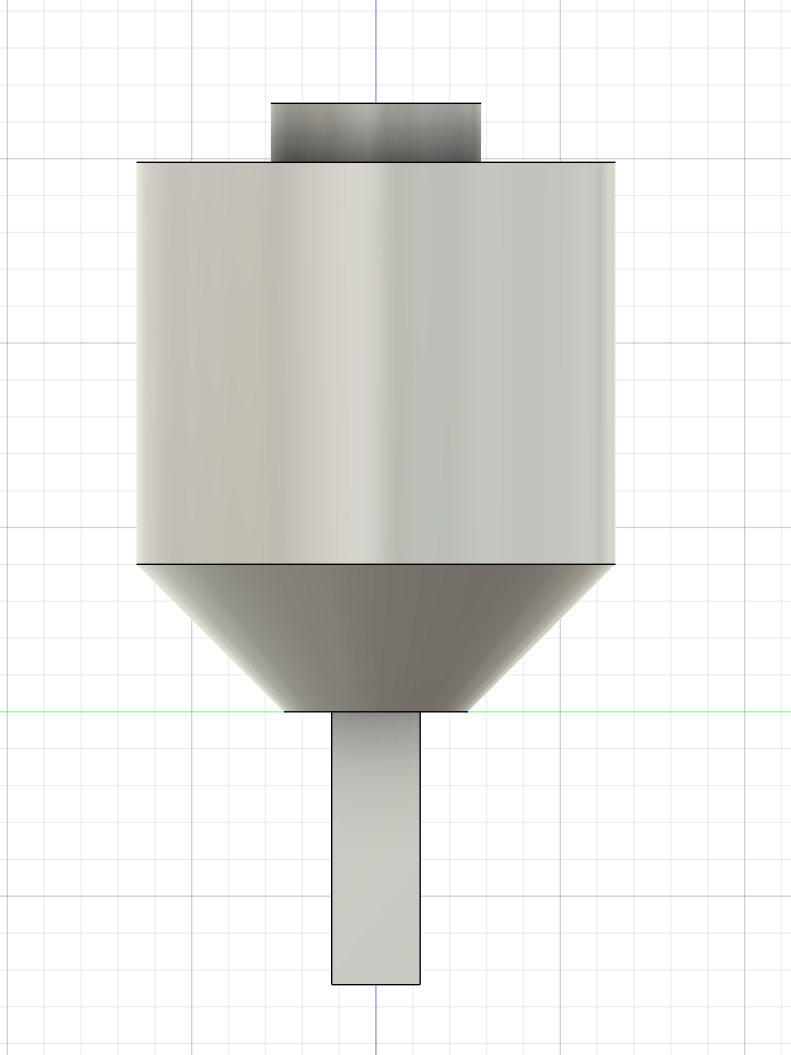

CAD images showing two views of the motor and where it would fit on the bike.

Final Prototype

We finished assembling at 2 am the day of our presentation. It wasn’t pretty, but it functioned, and we could reduce pedaling effort by around 20%.

Our final prototype used ratchet straps to mount the battery, a 3D printed motor mount, and a wireless throttle. Lots of design improvements came to mind, but time ended up as our biggest constraint.

Business Pitch

Not a lot of time was spent refining the business pitch. There was a market for affordable e-bike conversion kits, but we were not able to effectively communicate that to the judges. Judges liked the concept but they weren’t fans of the unpolished prototype. One even said it “looked like a bomb.” It worked, but it looked bad.

We didn’t end up winning anything solely because our pitch and presentation were not up to par.

What I Learned

The main thing I learned from my experience is that building is only as good as how well you communicate it. A product without a story won’t convince anyone of its value. I’m a computer science major, so it was nice to learn about physically designing and implementing something and all of the challenges that come with.

What I Would Do Differently

- Split effort more evenly between prototyping and pitching

- Design with aesthetics in mind

- Get feedback from non-technical people

I’m doing SPARK again my junior year to be able to apply those lessons. I have been spending most of my time on the pitch this year, and I am hoping to create a functioning prototype that can accompany a fantastic pitch.

Wrapping Up

AnyBike never became an actual product, but it’s reshaped my approach. I gained appreciation for the value that good communication can provide to any idea. A good prototype can prove it’s possible, but a good pitch can turn it into a business.